Since our latest test trip, I’ve been looking forward to finishing our pop-top roof. Yvonne and I considered both wedge and vertical tops, and we decided that a simple front-hinge wedge roof would be practical and lightweight for us.

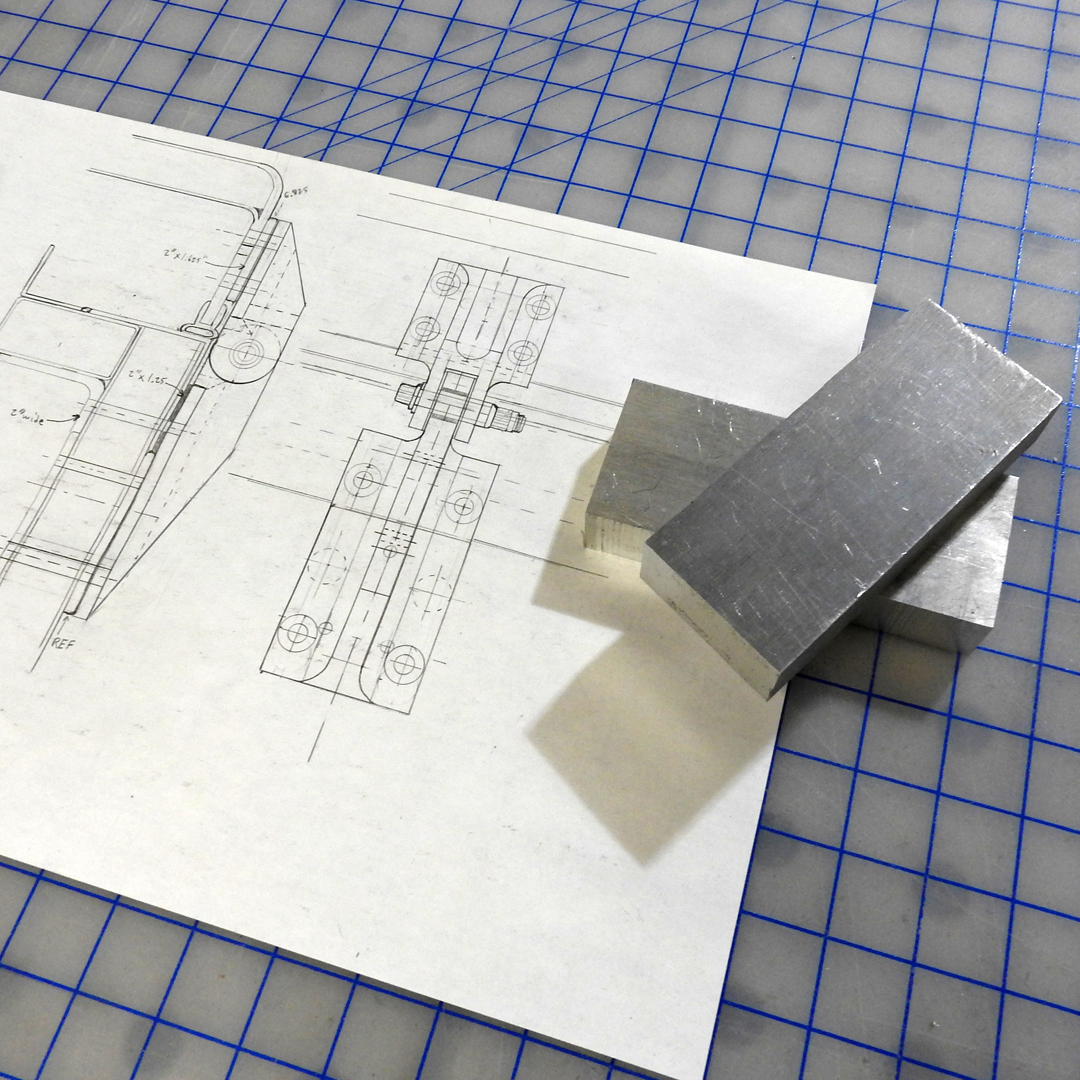

When looking at available hinges, I didn’t find any hinge options that were quite what I wanted, so I decided to make my own custom hinges that integrated well with our forward wall. I’ve used CAD for 30 years, but I decided that it would be fun to design the hinges with pencil and paper. Although a bit less efficient, drafting by hand just feels more creative to me compared to computer work.

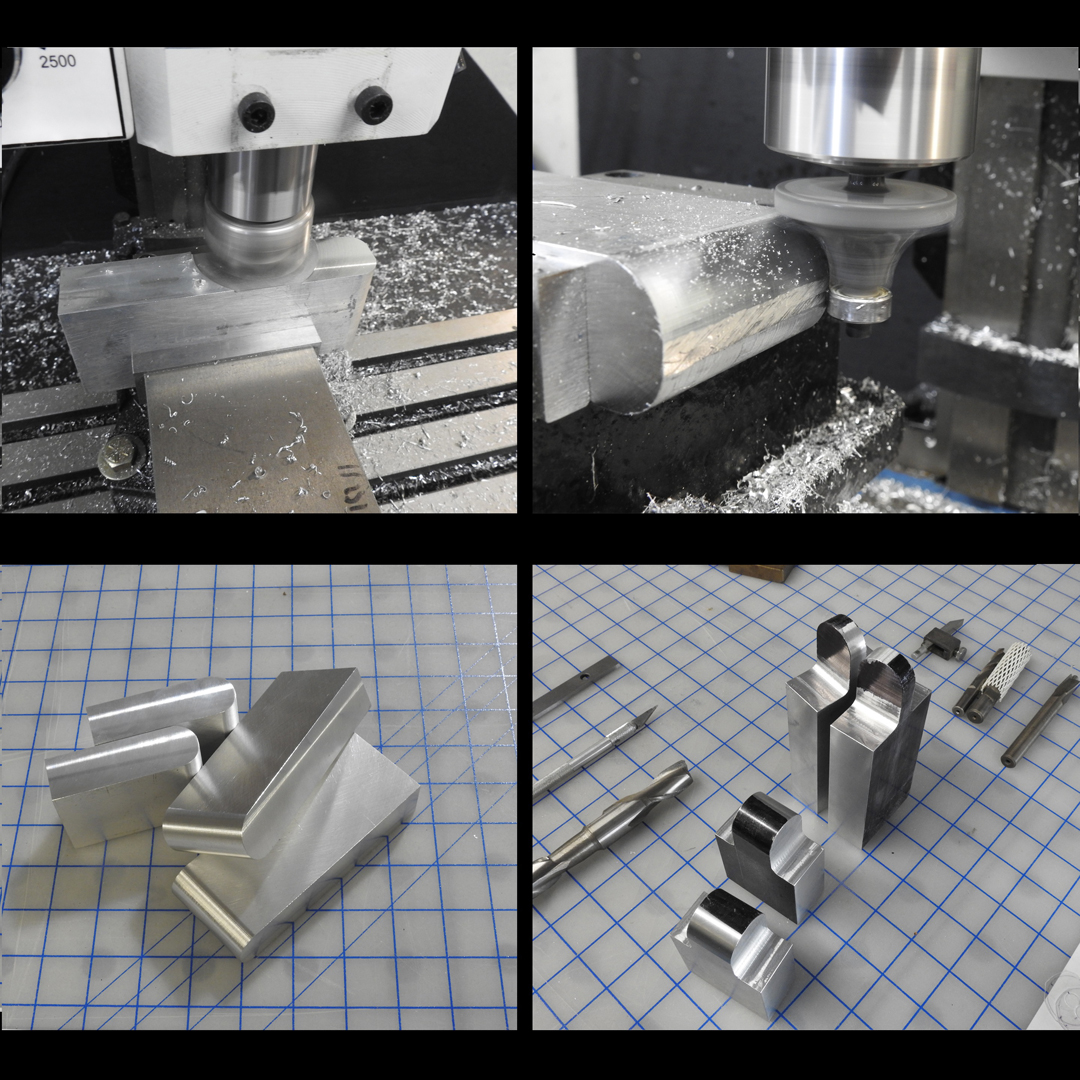

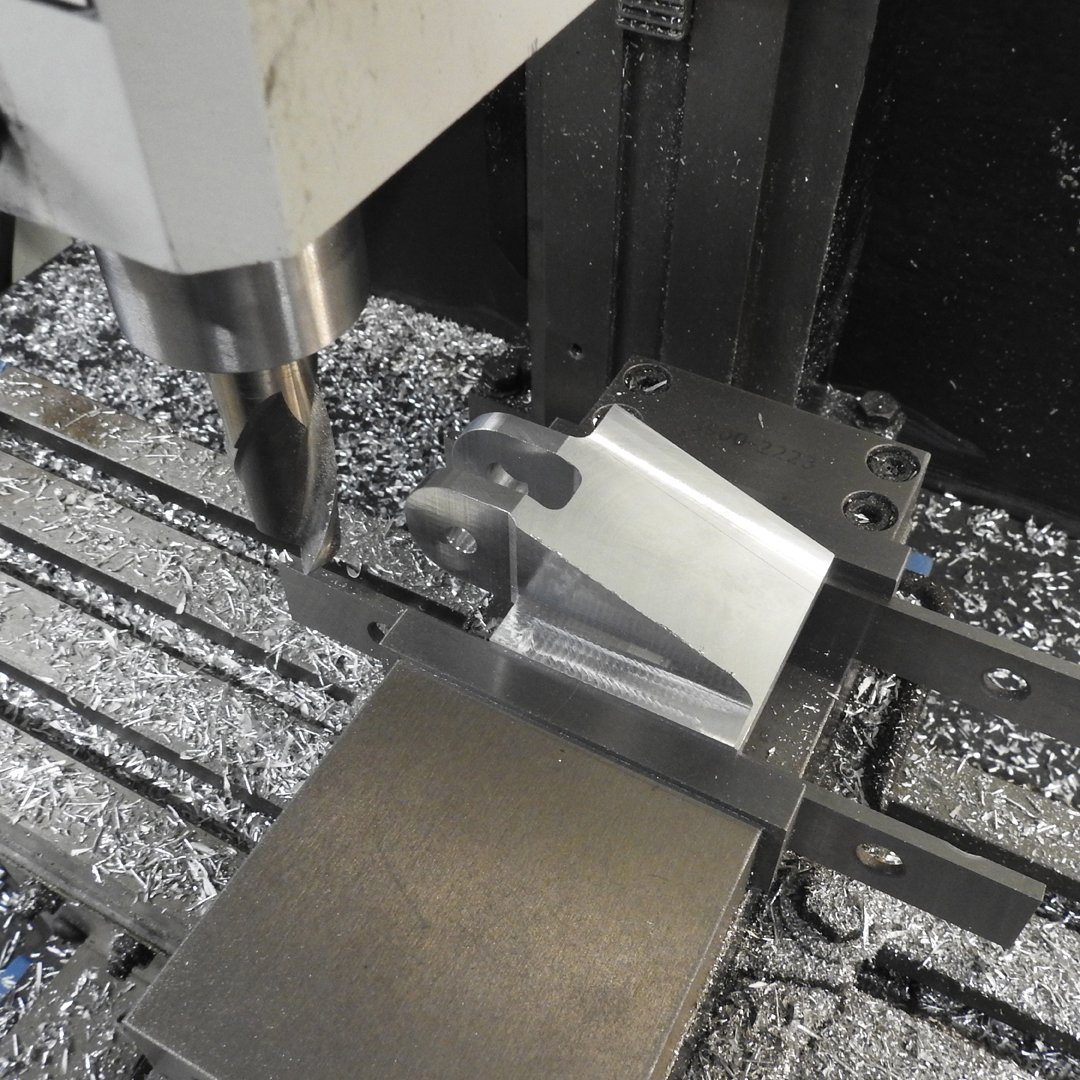

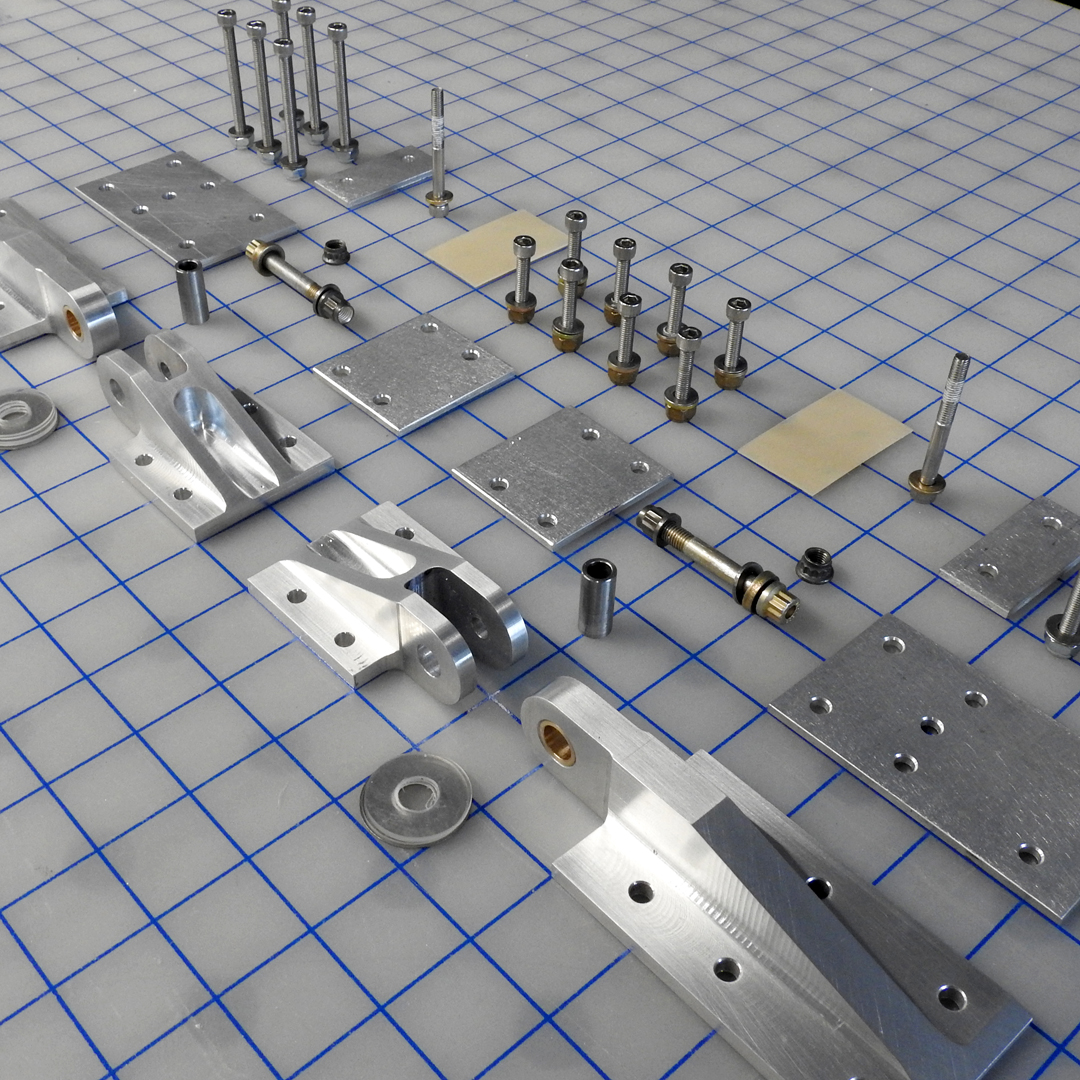

I designed the hinges like clevis/tang aircraft pivot joints. I turned the stainless pins and bronze bushings on my lathe, and I machined the hinges from 1” thick aluminum plate. It took me some time to machine all of the hinge parts, but they turned out well and they only weigh 0.44 lb each.

I decided to use gas struts for the roof lift, and I made a spreadsheet to calculate the optimal strut size, strut force rating, and mount positions using trigonometry. In addition to roof weight, I also considered wind aerodynamic loading, and the ergonomics of opening and closing the roof. I know the spreadsheet probably seems like overkill, but it really helped me dial in the strut mounting locations, if the struts were slanted forward or back, and pick the right gas struts. The roof has 32.5 inches of lift at the back, and that gives 7’3″ of ceiling height. The load to pull the roof closed feels appropriate.

It’s now time for the pop top cloth.

P.s. As you can see, Dan Grec’s jeep is here visiting while he is getting ready for his next round of upgrades.